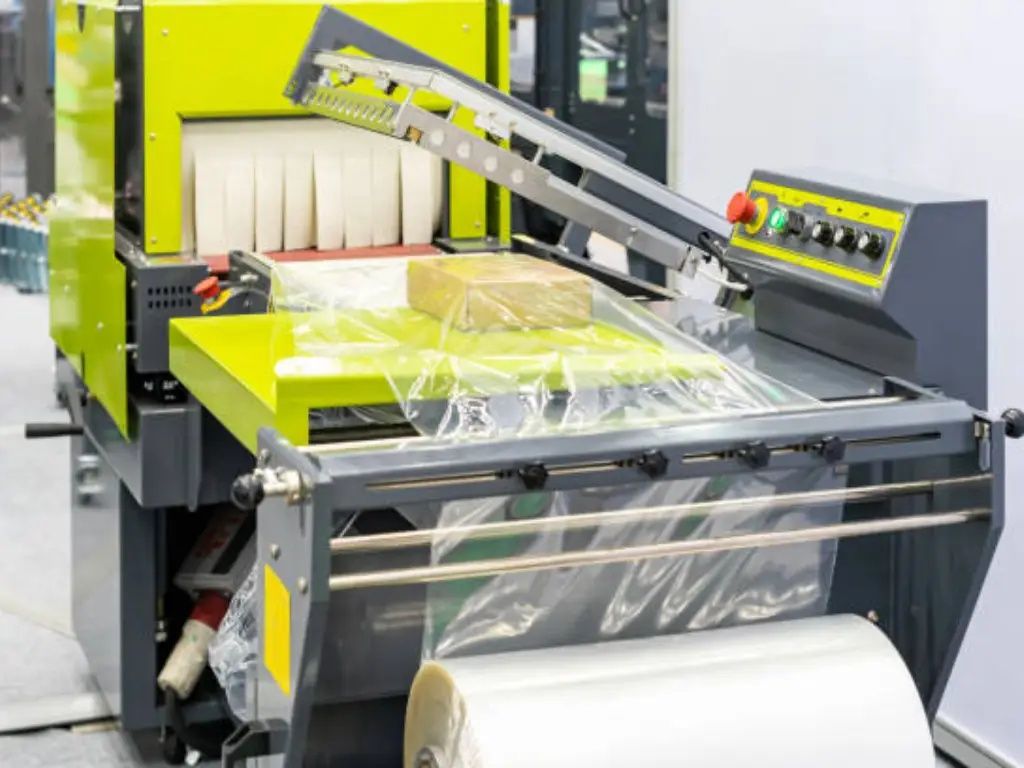

A Comprehensive Guide to Automated Shrink Wrapping Machines

Automated shrink wrapping machines are specialized equipment designed to encase products in a tight-fitting plastic film, which is then heated to shrink and conform to the product's shape. This process offers a secure and protective packaging solution, commonly used across various industries such as food and beverages, pharmaceuticals, and consumer goods.

The primary components of these machines include:

-

Film Roll: The plastic material that wraps around the product.

-

Sealing Bar: Where the film is cut and sealed.

-

Heat Tunnel: Applies heat to shrink the film around the product.

-

Conveyor System: Moves products through the machine.

These machines come in different configurations:

-

Semi-Automatic: Requires manual intervention for some steps.

-

Fully Automatic: Operates with minimal human involvement, ideal for high-volume production.

Significance in Modern Industries

Automated shrink wrapping machines play a crucial role in today's manufacturing and packaging sectors. Their importance is highlighted by several factors:

-

Efficiency: Speeds up the packaging process, reducing labor costs and increasing throughput.

-

Consistency: Ensures uniform packaging quality, enhancing product presentation.

-

Protection: Provides tamper-evident and moisture-resistant packaging, safeguarding products during transit and storage.

-

Compliance: Meets industry standards and regulations, particularly in sectors like food and pharmaceuticals.

These machines are particularly beneficial for businesses aiming to scale operations while maintaining packaging quality and safety.

Recent Developments and Trends

The past year has witnessed notable advancements in automated shrink wrapping technology:

-

Market Growth: The global shrink wrapping machines market continues to expand, reflecting increasing demand across industries.

-

Technological Innovations: New machines are capable of wrapping oversized and long products efficiently, optimizing space and throughput.

-

Sustainability Initiatives: Development of machines that reduce film usage and minimize waste, supporting environmental goals.

These trends indicate a shift towards more efficient, flexible, and eco-friendly packaging solutions.

Regulatory Landscape in India

In India, the use of automated shrink wrapping machines is influenced by various regulations:

-

Food Safety and Standards Authority of India (FSSAI): Sets guidelines for packaging materials and processes to ensure food safety.

-

Bureau of Indian Standards (BIS): Provides standards for packaging materials, including shrink films.

-

Environmental Regulations: Policies aimed at reducing plastic waste and promoting recycling affect the choice of materials used in shrink wrapping.

Adhering to these regulations is essential for manufacturers to ensure product safety and compliance with national standards.

Tools and Resources

Several tools and resources can assist in understanding and implementing automated shrink wrapping solutions:

-

Shrink Wrap Machine Calculators: Help determine the appropriate machine size and specifications based on product dimensions and production volume.

-

Industry Forums and Webinars: Platforms for discussions and insights from packaging professionals.

-

Regulatory Websites: Official sites provide up-to-date information on standards and regulations.

These resources are valuable for businesses considering the adoption of automated shrink wrapping technologies.

Frequently Asked Questions

1. What is the difference between semi-automatic and fully automatic shrink wrapping machines?

-

Semi-Automatic: Requires manual loading and unloading; suitable for lower production volumes.

-

Fully Automatic: Operates with minimal human intervention; ideal for high-volume production.

2. Can automated shrink wrapping machines handle different product sizes?

Yes, modern machines are designed to accommodate a range of product sizes and shapes, with adjustable settings to ensure proper wrapping.

3. Are there eco-friendly options available in shrink wrapping?

Yes, advancements have led to the development of machines that use biodegradable films and reduce material waste, supporting sustainability efforts.

4. How do I choose the right shrink wrapping machine for my business?

Consider factors like product dimensions, production volume, space availability, and compliance with industry regulations when selecting a machine.

5. What maintenance is required for these machines?

Regular cleaning, inspection of sealing bars, and calibration of heat settings are essential to ensure optimal performance and longevity of the machine.

Conclusion

Automated shrink wrapping machines are integral to modern packaging operations, offering efficiency, consistency, and compliance with industry standards. Understanding their components, significance, and the regulatory landscape is crucial for businesses aiming to enhance their packaging processes. By staying informed about recent developments and utilizing available resources, companies can make informed decisions about integrating these machines into their operations.