A comprehensive guide to UV machines in modern industry

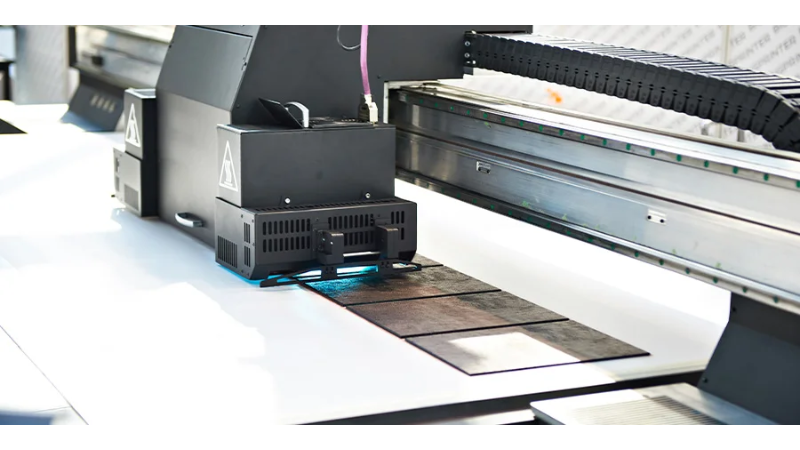

Ultraviolet (UV) machines are specialized industrial devices that use ultraviolet light—specifically UV-C wavelengths—for a variety of applications, ranging from disinfection and curing to surface treatment and inspection. These machines are used in industries like printing, electronics, packaging, automotive, medical devices, and even food processing.

UV technology works by emitting UV light to trigger chemical reactions or destroy microorganisms. Depending on the purpose, UV machines are fitted with different types of UV lamps or LEDs, and their designs vary from conveyor-based curing systems to enclosed disinfection cabinets.

In today’s industry, where hygiene, speed, and material efficiency are crucial, UV machines have become essential tools.

Why UV Machines Matter in Industry Today

UV machines are widely adopted across multiple sectors for a few key reasons:

1. Efficiency and Speed

In manufacturing, UV curing processes are much faster than conventional drying or bonding methods. For example, UV adhesives can bond materials in seconds without heating the product or affecting surrounding components.

2. Hygiene and Safety

UV-C machines are used for sterilization and disinfection. After the COVID-19 pandemic, their use surged in hospitals, airports, and factories for rapid surface disinfection without chemical residue.

3. Precision in Production

UV curing machines are ideal for precision applications like PCB coating, medical device assembly, or 3D printing, where tight control and minimal heat are required.

4. Sustainability

UV systems often use less energy and fewer consumables compared to traditional methods, making them attractive for companies aiming to reduce their carbon footprint.

Who Uses UV Machines?

-

Electronics manufacturers

-

Medical and pharmaceutical industries

-

Packaging and labeling companies

-

Printing and publishing houses

-

Food and beverage producers

-

Aerospace and automotive suppliers

Problems They Solve

Slow or inconsistent curing of coatings and inks

Risk of contamination in sensitive production environments

High energy consumption and emissions from heat-based methods

Manual labor and downtime associated with traditional disinfection

Trends and Updates in UV Technology

The UV machine industry continues to evolve, especially in the last year. Here are some of the key developments:

1. Shift to UV-LED Systems

Traditional mercury-based UV lamps are being replaced by UV-LED systems. LEDs are longer-lasting, energy-efficient, and mercury-free. According to MarketsandMarkets, the UV LED market is expected to reach $1.5 billion by 2026.

2. Integration with Automation

Many companies are integrating UV curing systems into robotic arms or conveyor lines. This improves consistency and supports continuous production. For example, in February 2024, a German electronics manufacturer adopted robotic UV curing to improve PCB processing time by 30%.

3. Portable UV Disinfection Devices

Portable or handheld UV-C devices gained traction in 2024, especially in pharmaceutical and cleanroom applications where spot sterilization is required. These machines are smaller, safer, and easier to use than past models.

4. Regulation-Driven Innovation

Because of stricter environmental and safety rules (especially regarding mercury), manufacturers are pushing for greener and safer alternatives, such as cold UV sterilization and ozone-free UV systems.

Regulatory Standards and Government Policies

UV machines are subject to multiple local and international regulations that affect their usage, design, and deployment.

Key Regulatory Bodies:

IEC (International Electrotechnical Commission) – Sets global safety standards for UV radiation.

FDA (U.S. Food and Drug Administration) – Regulates UV-C disinfection devices used in medical applications.

RoHS (Restriction of Hazardous Substances Directive) – Limits the use of mercury in UV lamps.

OSHA (Occupational Safety and Health Administration) – Mandates worker safety measures in UV environments.

Country-Specific Guidelines:

United States

The EPA and FDA jointly regulate UV-C sterilization for public health safety.

Mercury-based UV devices are being phased out under the Mercury Export Ban Act.

European Union

The EU requires that all UV-emitting machines comply with EN 62471 (Photobiological Safety).

Strict limits on mercury content under the updated RoHS Directive (2023) are forcing a move to LED-based UV systems.

India

The Bureau of Indian Standards (BIS) provides safety norms for UV germicidal devices.

In 2024, the Ministry of Health updated guidelines for UV disinfection in hospitals.

What This Means for Businesses

All industrial users must verify that UV equipment complies with safety and emissions standards.

Procurement teams should look for RoHS-compliant or LED-based systems to future-proof investments.

Workers operating UV machines must wear certified protective gear and follow exposure limits.

Tools, Resources, and Useful Platforms

If you're exploring UV machines for industrial use, several tools and websites can assist in planning, compliance, and decision-making.

Technical Tools and Calculators

UV Dose Calculators – Used to determine the required exposure time for effective disinfection or curing.

Try: uvtools.com

Irradiance Mapping Software – Helps simulate UV intensity across a surface to optimize lamp placement.

UV LED Efficiency Calculators – Useful for estimating long-term power savings and performance.

Standards and Compliance

IEC 62471 Document Access – www.iec.ch

RoHS Compliance Toolkits – www.rohsguide.com

Professional Associations

IUVA (International Ultraviolet Association) – Offers research, policy updates, and member access to best practices.

Website: www.iuva.org

Procurement and Comparison Platforms

Thomasnet and IndiaMART – Compare UV machine vendors by region, specs, and certifications.

UL Prospector – For validated material compatibility with UV curing.

Frequently Asked Questions (FAQs)

1. Are UV machines safe to use in workplaces?

UV machines are safe if used with proper shielding, ventilation, and protective equipment. Direct exposure to UV-C light can harm skin and eyes, so devices are usually enclosed or interlocked to prevent accidental exposure.

2. What's the difference between UV-A, UV-B, and UV-C machines?

UV-A (315–400 nm): Used mainly for inspection and curing.

UV-B (280–315 nm): Less common, used in specialty phototherapy.

UV-C (200–280 nm): Most commonly used for disinfection and sterilization.

3. How long does UV disinfection take?

The time varies depending on lamp power, distance, and target surface. For surface disinfection, effective exposure typically takes 5 to 10 minutes with UV-C.

4. Are mercury UV lamps being banned?

Yes, several regions, especially the EU and U.S., are gradually phasing out mercury lamps under environmental directives. UV-LED alternatives are being promoted as safer, greener replacements.

5. Can UV machines be used on food?

Yes, UV-C light is used to sterilize packaging and sometimes the outer surface of food (e.g., fruits). However, it must comply with food-grade standards and not alter taste or nutrition.

Final Thoughts

UV machines have evolved into indispensable tools across industrial sectors, offering fast, non-contact solutions for curing, bonding, and sterilizing. Their growing adoption is fueled by both technological innovation and stricter health and environmental standards.

For businesses, investing in the right UV system means balancing cost, compliance, efficiency, and future-readiness. For regulators and consumers, it ensures safety and sustainability in critical operations.

As the industry moves towards LED, automation, and safer practices, UV machines will continue playing a vital role in modern manufacturing, health care, and environmental safety.

Practical takeaway: When selecting a UV machine, consider your application (curing vs. sterilization), regulatory compliance, lamp type (LED vs. mercury), and safety measures. Investing wisely today can streamline operations and future-proof your facility.