Carton Sealing Machines: Complete Guide, Insights, and Tips for Efficient Packaging

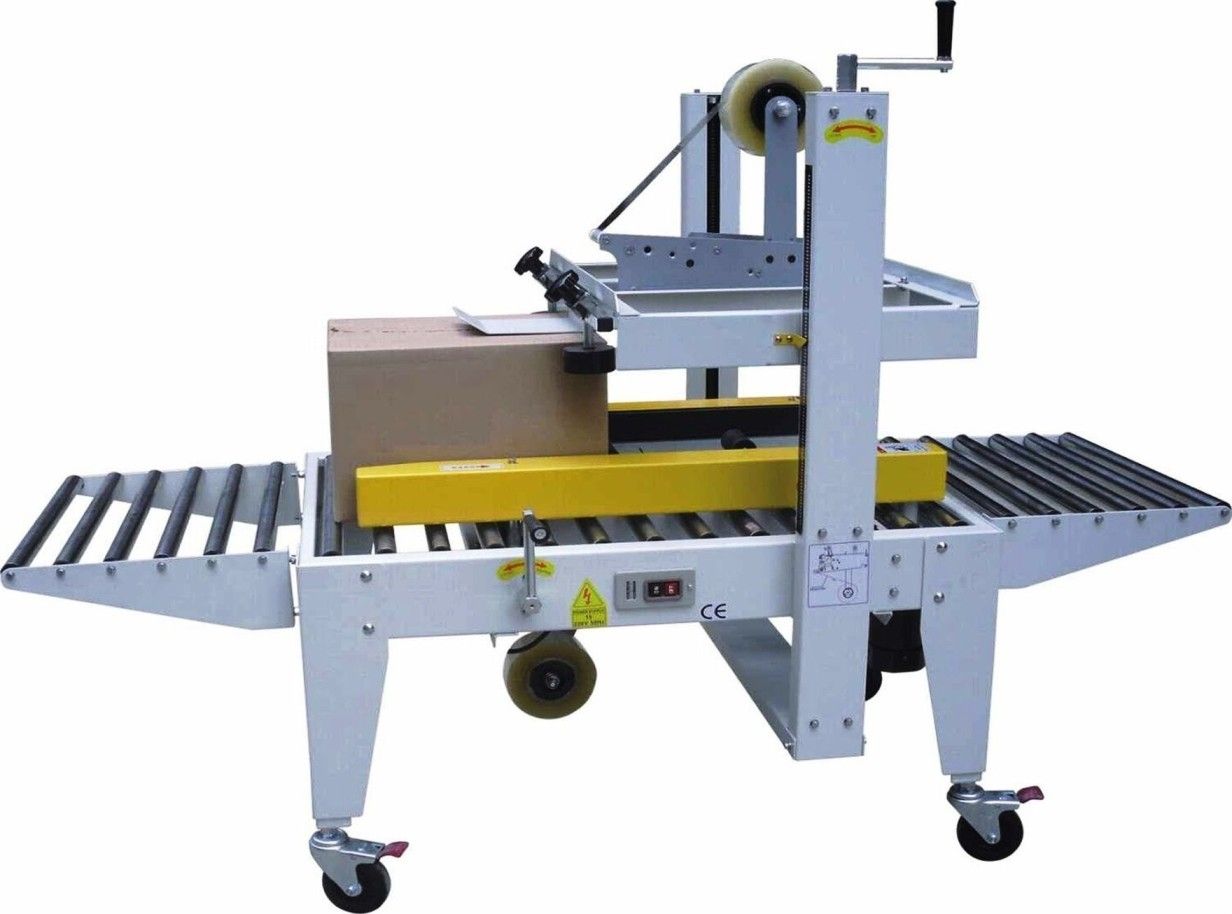

Carton sealing machines are automated devices designed to apply adhesive tape to the top and bottom flaps of cardboard boxes, ensuring secure closure for storage or shipping. These machines are integral to industries such as e-commerce, food and beverage, pharmaceuticals, and logistics, where efficient and consistent packaging is crucial.

There are primarily two types of carton sealing machines:

-

Manual Carton Sealers: Operated by hand, suitable for low-volume operations.

-

Automatic Carton Sealers: Automatically adjust to carton sizes and seal at higher speeds, ideal for high-volume production lines.

The choice between manual and automatic sealers depends on factors like production volume, budget, and required sealing speed.

Significance of Carton Sealing Machines Today

In today's fast-paced commercial environment, the demand for efficient and reliable packaging solutions has escalated. Carton sealing machines play a pivotal role in addressing several challenges:

-

Consistency: Automated sealing ensures uniform application of tape, reducing errors associated with manual sealing.

-

Speed: These machines can seal cartons at high speeds, enhancing throughput in packaging lines.

-

Cost Efficiency: By reducing labor costs and minimizing material wastage, carton sealing machines contribute to overall cost savings.

-

Product Protection: Securely sealed cartons protect products from damage during transit, preserving brand integrity.

Industries such as e-commerce and logistics have particularly benefited from the adoption of carton sealing machines, as they streamline packaging processes and meet the increasing demand for rapid order fulfillment.

Recent Developments in Carton Sealing Technology

The carton sealing machine market has witnessed notable advancements and trends in recent years:

-

Market Growth: The global carton sealer machine market continues to grow steadily, driven by increased demand from industries such as logistics, retail, and pharmaceuticals.

-

Automation Trends: There is a growing preference for fully automatic carton sealing machines due to their efficiency and ability to handle varying carton sizes without manual adjustments.

-

Sustainability Initiatives: Manufacturers are increasingly focusing on eco-friendly designs and materials, including biodegradable tapes and energy-efficient machines.

-

Integration with Smart Technologies: Incorporating IoT and machine learning allows for real-time monitoring, predictive maintenance, and improved machine reliability and performance.

Regulatory Framework Affecting Carton Sealing Machines

In India, the use of carton sealing machines is influenced by regulations aimed at safety, quality, and environmental sustainability:

-

Bureau of Indian Standards (BIS): Sets standards for packaging materials and machinery, ensuring that carton sealing machines meet quality and safety criteria.

-

Environmental Regulations: Guidelines encourage the use of eco-friendly materials to reduce non-biodegradable waste in packaging.

-

Labor Laws: Automated operations must comply with labor regulations to ensure worker safety and fair practices.

Following these regulations ensures compliance while promoting sustainable and ethical business operations.

Tools and Resources for Carton Sealing Machines

Several tools and resources can help optimize carton sealing operations:

-

Packaging Material Calculators: Determine tape requirements per carton to manage inventory efficiently.

-

Maintenance Checklists: Guide operators in routine inspections and servicing to ensure machine longevity.

-

Training Modules: Online tutorials and courses train staff on proper operation and troubleshooting.

-

Industry Forums: Platforms for sharing best practices, insights, and operational experiences.

Using these resources can enhance efficiency, reduce downtime, and improve overall productivity.

Frequently Asked Questions

1. What is the difference between manual and automatic carton sealing machines?

Manual machines require operator intervention for each carton, while automatic machines adjust to various carton sizes and seal at higher speeds.

2. How do carton sealing machines contribute to cost savings?

Automation reduces labor costs, minimizes material wastage, and increases production efficiency.

3. Are eco-friendly options available for carton sealing machines?

Yes, machines using biodegradable tapes and energy-efficient designs are increasingly available.

4. How often should a carton sealing machine be maintained?

Regular maintenance should follow manufacturer guidelines for inspection and servicing intervals.

5. Can carton sealing machines handle different carton sizes?

Modern automatic machines are designed to adjust to multiple carton sizes for flexibility in packaging operations.

Conclusion

Carton sealing machines are crucial for modern packaging operations, offering efficiency, consistency, and cost-saving advantages. Advances in automation, sustainability, and smart technologies continue to improve their performance. By understanding their importance, keeping up with trends, and following regulatory standards, businesses can optimize packaging processes and enhance operational reliability.