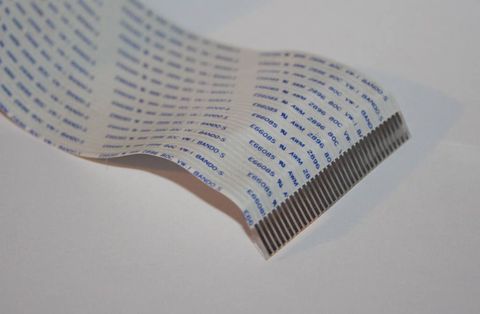

Heat Shrink Fabric Explained: Discover Core Knowledge, Applications, and Useful Resources

Heat shrink fabric is a specialized industrial material designed to contract when exposed to heat, forming a tight and uniform covering around objects. It is commonly made from heat-resistant polymers, including polyolefin materials, polyester blends, and advanced engineering fibers that maintain structural stability during controlled heating. This fabric exists to create a durable protective layer for wires, structural components, equipment parts, and surfaces that require insulation or reinforcement.

The use of heat shrink fabric developed from the need for a flexible yet strong covering solution that adapts to various shapes without requiring complex manufacturing steps. Over time, it has become standard in industries such as aviation, automotive, marine engineering, electrical insulation, and packaging. Its ability to deliver uniform coverage, resistance to abrasion, and enhanced thermal stability makes it a preferred choice for situations where precision and durability matter.

Heat shrink fabric functions by undergoing a predictable contraction when heated using equipment such as industrial heat guns, hot air tunnels, or controlled ovens. This physical transformation allows it to bond securely to underlying surfaces, creating a seamless layer that improves protection, appearance, and structural performance.

Importance

Heat shrink fabric plays a significant role in today’s material engineering environment. Its importance is reflected in how it supports safety, organization, longevity, and performance across a wide range of applications.

Industries rely on heat shrink fabric for several reasons:

-

Protection of sensitive components

It shields wiring harnesses, pipes, cables, and mechanical joints from moisture, dust, UV exposure, and mechanical wear. -

Thermal insulation

Heat shrink fabric enhances thermal resistance, making it valuable in systems that operate in high-temperature environments. -

Structural reinforcement

The fabric strengthens surfaces, reduces vibration, and prevents surface degradation. -

Material identification and organization

Color-coded heat shrink fabric is used for labeling electrical systems and organizing complex assemblies. -

Improved durability and performance

In aircraft assembly, automotive manufacturing, and machinery maintenance, heat shrink fabric supports reliability and reduced maintenance needs.

The topic affects engineers, technicians, fabricators, electrical specialists, product designers, and industries that handle sensitive materials or structural assemblies. It helps solve problems related to component failure, exposure damage, inconsistent insulation, and long-term reliability issues.

Recent Updates

Heat shrink fabric has seen ongoing innovation as industries demand lighter, stronger, and more environmentally conscious materials. Over the past year, several notable trends and updates have appeared:

-

Improved heat-resistant polymers (2024–2025)

Manufacturers have introduced fabrics with better flame-retardant properties and enhanced mechanical strength to meet evolving industrial safety standards. -

Shift toward recyclable and eco-aligned materials (2024)

With sustainability gaining global attention, new versions of heat shrink fabric now incorporate recyclable polymer blends and reduced-emission production methods. -

Adoption in renewable energy systems (2024–2025)

Heat shrink materials are increasingly used in solar installations, wind turbines, and energy storage systems due to their thermal insulation and protective functions. -

Advancements in aerospace applications (2025)

The aerospace sector has adopted high-performance heat shrink fabric for wiring protection in lightweight aircraft structures. -

Enhanced testing guidelines (2024)

Updated standards now emphasize temperature tolerance testing and improved mechanical stress assessments for industrial shrink fabrics.

These developments reflect growing demand for safer, more efficient, and more durable industrial materials.

Laws or Policies

Heat shrink fabric usage is influenced by various national and international regulations that guide safety, material performance, and environmental impact. While rules differ between countries, several common areas apply:

-

Electrical insulation standards

Heat shrink fabric used in wiring systems often must comply with standards like IEC requirements, national electrical safety codes, and material-specific testing procedures. -

Fire safety guidelines

Flame-retardant properties may be required in industries such as construction, transportation, and aviation. Certifications typically involve heat resistance tests, smoke toxicity evaluations, and thermal endurance ratings. -

Environmental compliance

Many countries follow guidelines related to material composition, including restrictions on hazardous substances and requirements for recyclable polymers. -

Industrial safety programs

Workplace regulations often outline proper usage of heat shrink equipment, safe heating procedures, and handling requirements to minimize risk. -

Quality management frameworks

Organizations working with heat shrink materials frequently follow standards like ISO quality testing procedures to ensure reliability and performance consistency.

These policies help maintain safe and responsible use across industries.

Tools and Resources

Several tools, references, and online resources support understanding and application of heat shrink fabric:

-

Heating equipment

-

Industrial heat guns

-

Temperature-controlled hot air systems

-

Heat tunnels used in packaging and manufacturing

-

Laboratory ovens for precision shrinking tests

-

-

Material specification databases

-

Polymer information libraries

-

Engineering material comparison tools

-

Online insulation thickness calculators

-

-

Industry guidelines and documentation

-

Electrical safety code resources

-

Material property charts

-

Application manuals for thermal insulation processes

-

-

Training resources

-

Online publications covering industrial materials

-

Technical reference guides

-

Educational videos on shrink-based applications

-

Example Table: Common Types of Heat Shrink Fabric

| Material Type | Key Properties | Common Uses |

|---|---|---|

| Polyolefin Fiber | Flexible, heat-resistant, durable | Electrical insulation, cable bundling |

| Polyester Blend | High mechanical strength, UV-resistant | Outdoor equipment, marine wiring |

| Glass Fiber Fabric | Excellent thermal stability | High-temperature insulation |

| PVC Coated Weave | Chemical-resistant and protective | Industrial covering, machinery wraps |

Example Table: Typical Temperature Ranges

| Application | Shrink Temperature | Notes |

|---|---|---|

| Electrical Sleeving | 90–120°C | Light-duty insulation |

| Industrial Wrapping | 120–160°C | Tight fit for large components |

| Aerospace Components | 160–200°C | High-performance materials |

FAQs

What is heat shrink fabric used for?

Heat shrink fabric is used for protective covering, insulation, reinforcement, and organization of components such as cables, pipes, and mechanical assemblies. It forms a secure layer after heat application.

What materials are commonly used to make heat shrink fabric?

The fabric is typically made from polymers such as polyolefin, polyester, PVC blends, and specialized engineering fibers that maintain stability at elevated temperatures.

How does heat shrink fabric differ from heat shrink tubing?

Heat shrink tubing is a pre-shaped cylindrical form, while heat shrink fabric is flexible, sheet-like, and adaptable to irregular shapes. Both rely on heat-activated contraction but serve different structural needs.

Is heat shrink fabric suitable for outdoor environments?

Many versions are designed for outdoor use and offer UV resistance, moisture protection, and durability. Material selection depends on environmental conditions.

Can heat shrink fabric improve thermal insulation?

Yes. Its layered structure enhances insulation and helps protect components in high-temperature or thermally demanding environments.

Conclusion

Heat shrink fabric has become an essential material in modern engineering, manufacturing, and technical assembly due to its adaptability, protective qualities, and ability to enhance structural performance. Its use continues to grow as industries demand better thermal insulation, improved component safety, and higher-quality materials. Recent developments in polymers, sustainability, and industry testing have expanded the capabilities of heat shrink fabric, making it suitable for increasingly complex applications.

As industries evolve, understanding how heat shrink fabric works, where it is applied, and what standards guide its usage remains essential. The material's combination of durability, flexibility, and predictable heat-activated behavior ensures its ongoing relevance in electrical systems, industrial machinery, aerospace engineering, and many other fields.